Whats is STP

STS provides best solution for sewage treatment plant (STP) association with Sintex plastics technology. Two variants of Sintex sewage treatment plants available based on capacity and operating principle..

Sinex Sewage treatment plants are compact and can be used in a decentralized manner anywhere for proper treatment.

Sintex Sewage treatment plants are based on aerobic and anaerobic process and are designed to have dual functions for efficient treatment of domestic wastewater from toilets, bathrooms, kitchens and washing area.

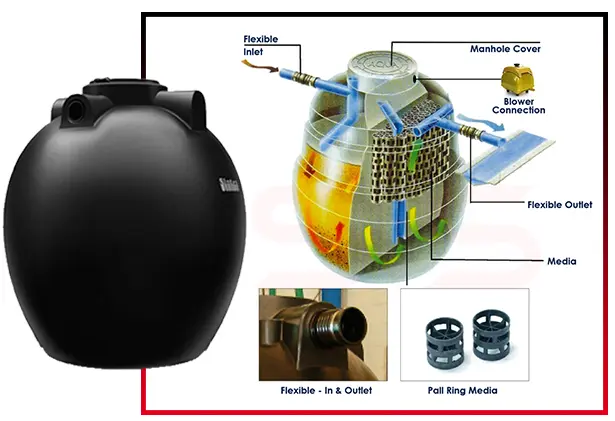

Packaged Sewage treatment plants (PSTP_STBF Series, Cap : 1.2KLD to 6KLD)

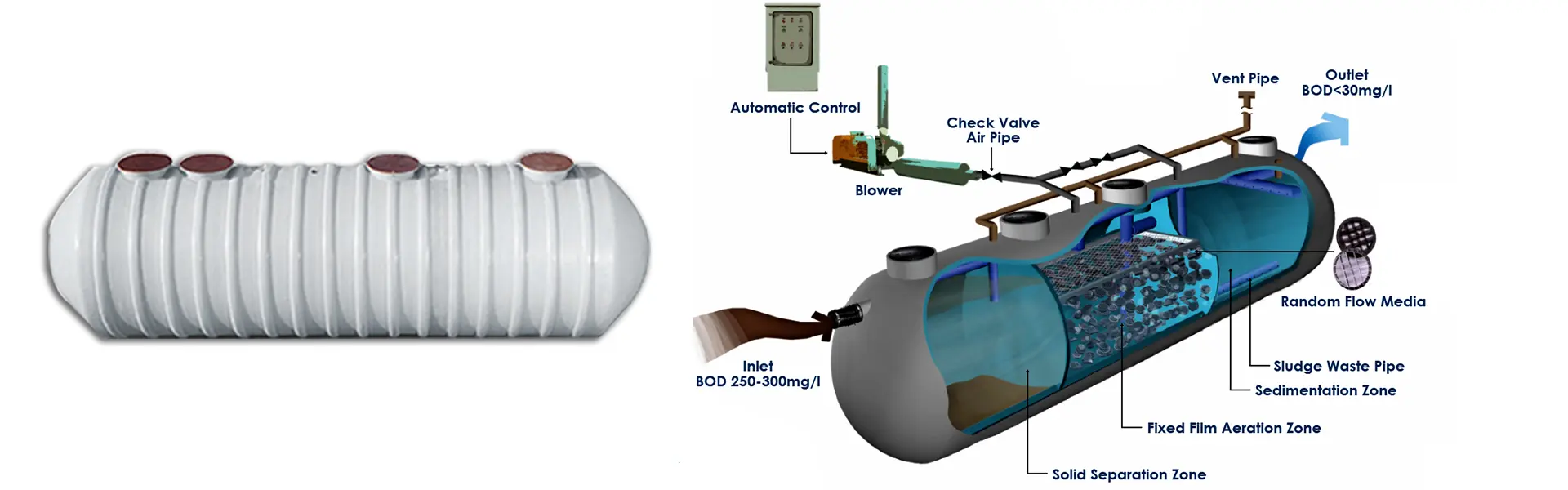

Packaged Sewage treatment plants (PSTP_NBF Series, Cap : 10KLD to 150KLD)